Product List

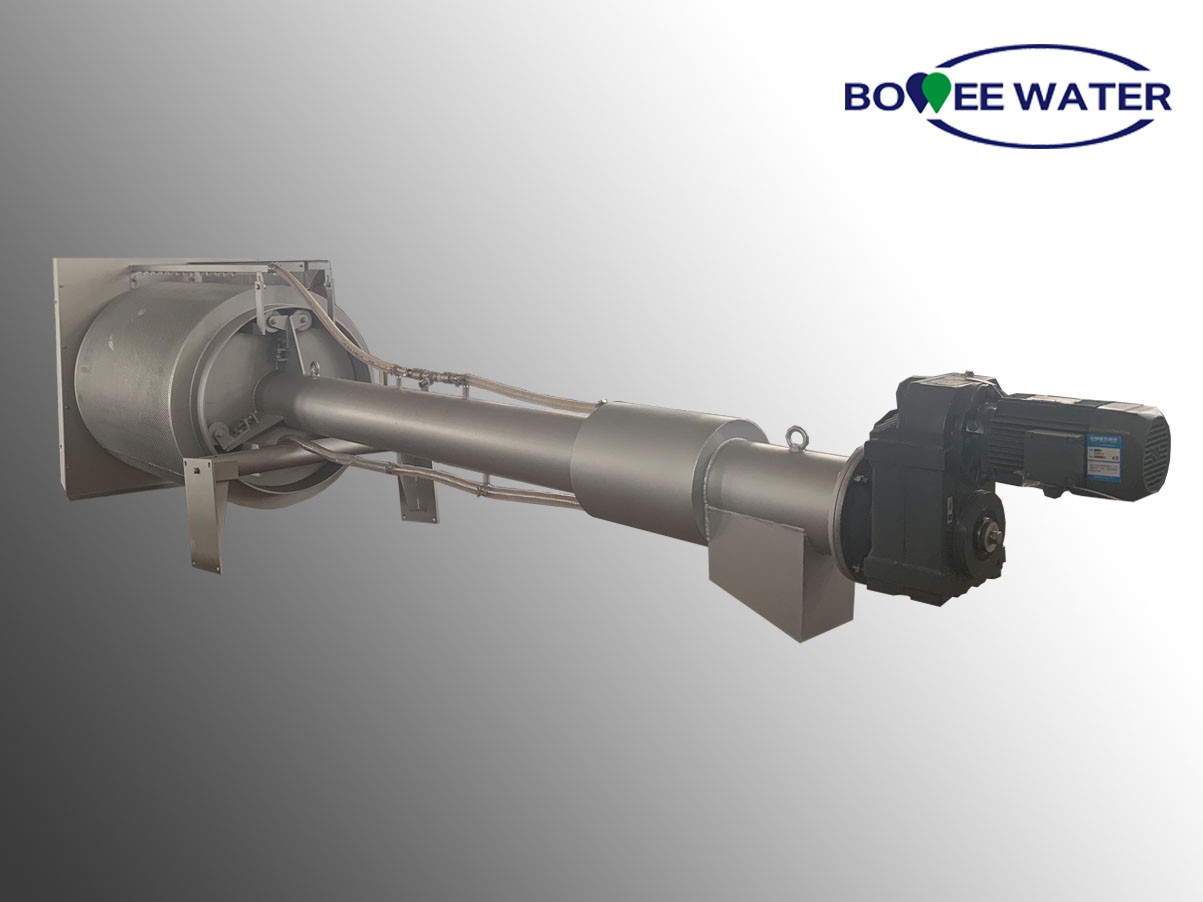

Rotary drum screen(in channel) is a new type of product developed & produced by BOWEE which absorbed foreign advanced technology & combined actual condition of domestic water treatment.

Specifications:

Dimension: Customized

Material: SS304, SS316 or Customized

Mesh opening: 0.5-10mm

Opening type: Wedge wire or Perforated

Self-cleaning type: Brush and spraying water

Inclined angle: 35°

Motor brand: First-class motor, Nord or SEW is optional

-

Description

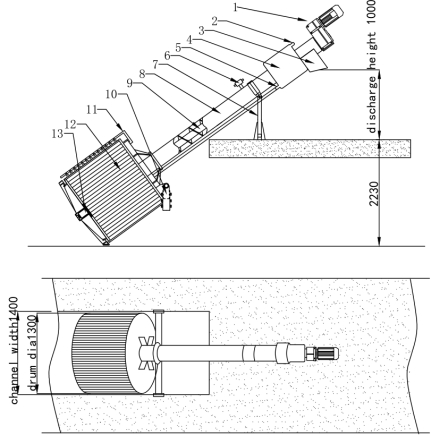

Rotary drum screen(in channel) is a new type of product developed & produced by BOWEE which absorbed foreign advanced technology & combined actual condition of domestic water treatment. It is the fine screen which integrates residue collecting, conveying and dewatering together and been widely used for municipal wastewater treatment plant. The rotary drum screen is composed of cylindrical screen drum, the installation angle is 35. Residues get blocked and stored on the inner surface of screen drum while flowing by. The whole cylindrical drum which is driven by motor, drum surface washed by brush and spraying water. Residue blocked by deslagging plate dropped into the collecting hopper & delivered by central screw conveyor, and finally fell into waste cart from discharge outlet for outward transport. There are two kinds of screen, perforated screen and wedge wire.

-

Applications

· Municipal Sewage treatment

· Papermaking wastewater

· Water Treatment Plant

· Leather industry

· Beverage industry

· Slaughterhouse

· Pharmaceutical wastewater

· Food industry

· Petrochemical industry

· Textile industry

-

Technical parameters

Model

Parameters

BWDIC-600

BWDIC-800

BWDIC-1000

BWDIC-1200

BWDIC-1400

BWDIC-1600

BWDIC-1800

BWDIC-2000

Screen width(mm)

600

800

1000

1200

1400

1600

1800

2000

Channel width(mm)

700

900

1100

1300

1500

1700

1900

2100

Installation angel(°)

35°

Channel depth(mm)

Customized

Discharge height

1000-1500

Rotating speed(rpm)

6

1.Gearbox 2.Clean water inlet 3.Discharge port 4.Screw barrel 5.Screw outlet 6. Solenoid valve and inlet nozzle 7.Support 8.Screw pipe 9.Screw press 10.Support 11.Cleaning system 12.Drum screen 13. Underwater bearing

-

Advantages

· Little hydraulic loss, high efficiency, and large processing capacity.

· Whole stainless steel structure, convenient in maintenance and long service life.

· The working device of the equipment can clean the equipment by itself.

· A system with more functions, and structure compact.

-

Related Products